Pneumatic Conveyors

Pneumatic conveying is generally the most efficient and effective method of transporting granular and bulk solid materials to storage or to process within a production environment.

Pneumatic Conveying is simple, reliable and flexible. It is designed to be a simple yet effective method of transferring material from a single collection point to either single or multiple reception points. Pneumatic Conveying can be used throughout industry to transfer all types of bulk solid materials ranging from fine cohesive powders to wet lump coal. The conveying process is enclosed and dust-free. This ensures that material transfer complies with strict COSHH regulations as well as other international industry regulations. Pneumatic Conveying is also less harmful to the environment than traditional mechanical methods.

Dense Phase Pneumatic Conveying is suitable for the transportation of difficult, abrasive or friable materials. This method of conveying pushes the material along a pipeline in a plug form at relatively low velocities (2-8 metres per second). This means minimal wear on pipelines and bends, which promotes minimal maintenance and long life on system components. Efficient use of compressed air also generates low power consumption and reduces running costs.

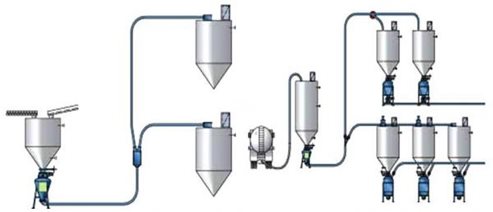

A Dense Phase Pneumatic Conveying system is shown in the above animation. The system consists of a pressure vessel and control valves, used to manage the flow of material fed into, and out of, the conveying vessel. The Dense Phase systems can convey materials over significant distances (up to 1,5 km) and at tonnage rates of up to 450 TPH.